Remove paint, primer, rust, and body filler in just one step.

Water reduces friction and heat, which are normally responsible for warping.

Adjust your pressure and media to go from blasting fiberglass to solid steel.

Rust Inhibitor keeps the surface clean and free of flash rust for 72 hours.

Adjust blast pressure to suit a variety of surfaces including concrete, brick, and wood.

Recycled glass abrasive is environmentally inert and will not harm vegetation.

Dust is suppressed, so you can work safely in urban environments and even indoors.

Instead of water alone, the Dustless Blaster uses blast abrasive for powerful coating removal.

Others can continue working nearby while blasting is being performed.

Reduced dust means easier containment and cleanup.

Steel, aluminum or fiberglass... you won't warp or damage the substrate.

Remove antifouling paint, epoxy, heavy marine growth, or open blisters in the gelcoat.

No hazardous and caustic chemical strippers to deal with.

Unlike chemical stripping, blasting leaves an anchor profile for the new coating to adhere to.

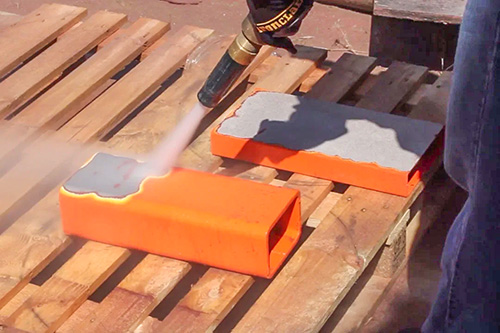

Water cools the powder coat, making it brittle. This allows it to flake off as opposed to getting gooey, like it does with the heat generated from dry blasting

Water suppresses the dust plume, letting you work with less containment and cleanup.

Pressure and flow are easily adjustable, for cleaning a variety of surfaces including antique brick.

Recycled glass media ensures that you won't harm nearby plant life and will comply with governmental regulations.

Wet blasting is recommended by OSHA to protect workers from potentially hazardous airborne particles.

Paint, stain, sealer, grime, graffiti, line stripes, calcium or oil stains, mildew and more.

Tackle paint, sealer, oil stains, tar, and even thermoplastic — leaving no trace behind.

A wet delivery method, like Dustless Blasting, is recommended by OSHA to protect workers from potentially hazardous airborne particles.

Because our process suppresses dust, it’s ideal for confined spaces, like parking garages.

Add revenue streams to your business by etching designs into concrete.

Adjust the blast pressure to suit any surface, even antique wood.

Choose from a wide variety of blast abrasives, including soda and organics.

Dust is suppressed, so you can work in residential areas and even indoors.

Powerful when you need it. Use stencils to etch custom designs in wood.

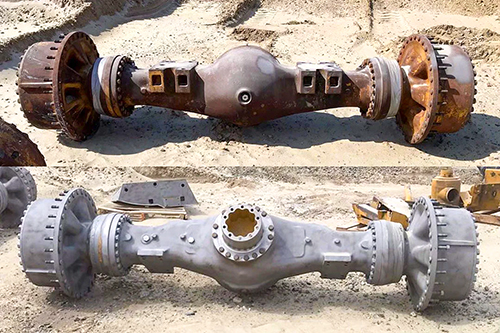

A powerful mixture of water and abrasive obliterates industrial-strength coatings with ease.

The fast process with minimal cleanup gets you back up and running in no time compared to other methods.

By removing rust and other contaminants, you’ll extend the lifespan of your machinery and see better performance.

Blast wet or dry with a variety of abrasives, including crushed glass, slag, garnet, and more.

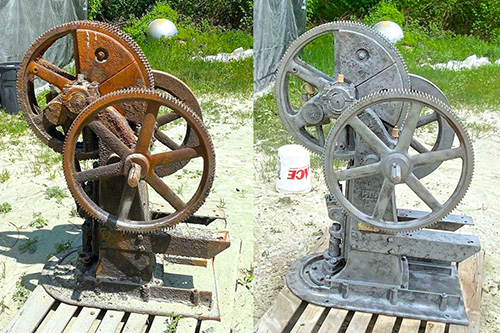

The water in our process reduces friction and heat, which can cause warping with other methods.

Blast around rivets and other hard to reach places.

Water suppresses the dust plume, making containment and cleanup simple.

Remove old paint and decals from fleet vehicles and keep up with their constantly updating graphics.

For delicate substrates, choose to blast with a soda, walnut, or other soft abrasives.

Strip away years of rust and grime.

Save history by breathing new life into old antiques.

Blast wet or dry with a variety of eco-friendly abrasives based on the job.

Remove charring, soot, and other types of residue caused by a fire.

Blast with sodium bicarbonate (soda blasting) to clean & deodorize simultaneously.

Get homes and businesses back to their pre-fire condition.

Blast wet or dry with a variety of eco-friendly abrasives based on the job.